You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

ContinueCancelclearAll articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer tohttps://www.mdpi.com/openaccess.

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

JournalsActive JournalsFind a JournalJournal ProposalProceedings Series Topics InformationFor AuthorsFor ReviewersFor EditorsFor LibrariansFor PublishersFor SocietiesFor Conference OrganizersOpen Access PolicyInstitutional Open Access ProgramSpecial Issues GuidelinesEditorial ProcessResearch and Publication EthicsArticle Processing ChargesAwardsTestimonialsEditing Services InitiativesSciforumMDPI BooksPreprints.orgScilitSciProfilesEncyclopediaJAMSProceedings Series AboutOverviewContactCareers News PressBlogSign In / Sign UpSubmit JournalsNanomaterialsVolume 10Issue 410.3390/nano10040641

JournalsActive JournalsFind a JournalJournal ProposalProceedings Series Topics InformationFor AuthorsFor ReviewersFor EditorsFor LibrariansFor PublishersFor SocietiesFor Conference OrganizersOpen Access PolicyInstitutional Open Access ProgramSpecial Issues GuidelinesEditorial ProcessResearch and Publication EthicsArticle Processing ChargesAwardsTestimonialsEditing Services InitiativesSciforumMDPI BooksPreprints.orgScilitSciProfilesEncyclopediaJAMSProceedings Series AboutOverviewContactCareers News PressBlogSign In / Sign UpSubmit JournalsNanomaterialsVolume 10Issue 410.3390/nano10040641 Submit to this JournalReview for this JournalPropose a Special Issue►▼Article MenuArticle MenuSubscribe SciFeedRecommended ArticlesRelated Info LinksPubMed/MedlineGoogle ScholarMore by Authors Linkson DOAJRen, Z.Zhu, Y.Wu, Q.Zhu, M.Guo, F.Yu, H.Yu, J.on Google ScholarRen, Z.Zhu, Y.Wu, Q.Zhu, M.Guo, F.Yu, H.Yu, J.on PubMedRen, Z.Zhu, Y.Wu, Q.Zhu, M.Guo, F.Yu, H.Yu, J./ajax/scifeed/subscribeArticle ViewsCitations-Table of ContentsAltmetricshareShareannouncementHelpformat_quoteCitequestion_answerDiscuss in SciProfilesthumb_up...Endorsetextsms...CommentNeed Help?Support

Submit to this JournalReview for this JournalPropose a Special Issue►▼Article MenuArticle MenuSubscribe SciFeedRecommended ArticlesRelated Info LinksPubMed/MedlineGoogle ScholarMore by Authors Linkson DOAJRen, Z.Zhu, Y.Wu, Q.Zhu, M.Guo, F.Yu, H.Yu, J.on Google ScholarRen, Z.Zhu, Y.Wu, Q.Zhu, M.Guo, F.Yu, H.Yu, J.on PubMedRen, Z.Zhu, Y.Wu, Q.Zhu, M.Guo, F.Yu, H.Yu, J./ajax/scifeed/subscribeArticle ViewsCitations-Table of ContentsAltmetricshareShareannouncementHelpformat_quoteCitequestion_answerDiscuss in SciProfilesthumb_up...Endorsetextsms...CommentNeed Help?SupportFind support for a specific problem in the support section of our website.

Get SupportFeedbackPlease let us know what you think of our products and services.

Give FeedbackInformationVisit our dedicated information section to learn more about MDPI.

Get InformationclearJSmol Viewerclearfirst_page Download PDFsettingsOrder Article ReprintsFont Type:ArialGeorgiaVerdanaFont Size:AaAaAaLine Spacing:Column Width:Background:Open AccessArticleEnhanced Storage Stability of Different Polymer Modified Asphalt Binders through Nano-Montmorillonite ModificationbyZhibin Ren Zhibin RenSciProfilesScilitPreprints.orgGoogle Scholar 1,2,3

Zhibin RenSciProfilesScilitPreprints.orgGoogle Scholar 1,2,3 , Yongqiang Zhu

, Yongqiang Zhu Yongqiang ZhuSciProfilesScilitPreprints.orgGoogle Scholar 4, Qi Wu

Yongqiang ZhuSciProfilesScilitPreprints.orgGoogle Scholar 4, Qi Wu Qi WuSciProfilesScilitPreprints.orgGoogle Scholar 5, Minye Zhu

Qi WuSciProfilesScilitPreprints.orgGoogle Scholar 5, Minye Zhu Minye ZhuSciProfilesScilitPreprints.orgGoogle Scholar 2, Feng Guo

Minye ZhuSciProfilesScilitPreprints.orgGoogle Scholar 2, Feng Guo Feng GuoSciProfilesScilitPreprints.orgGoogle Scholar 6, Huayang Yu

Feng GuoSciProfilesScilitPreprints.orgGoogle Scholar 6, Huayang Yu Huayang YuSciProfilesScilitPreprints.orgGoogle Scholar 3,* and Jiangmiao Yu

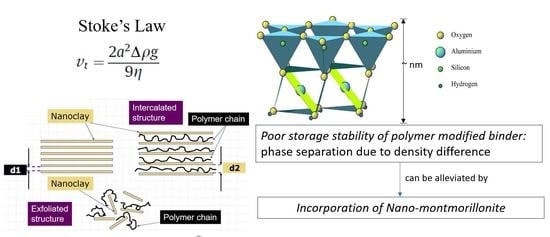

Huayang YuSciProfilesScilitPreprints.orgGoogle Scholar 3,* and Jiangmiao Yu Jiangmiao YuSciProfilesScilitPreprints.orgGoogle Scholar 2,*1Research and Development Centre of Transport Industry of Technologies, Materials and Equipment of Highway Construction and Maintenance, Gansu Road and Bridge Group Co. Ltd., Lanzhou 730050, China2School of Civil Engineering and Transportation, South China University of Technology, Wushan Road, Tianhe District, Guangzhou 510000, China3Key Laboratory for Special Area Highway Engineering, Chang’an University, Xi’an 710064, China4Guangdong Guanyue Highway & Bridge Co., Ltd., Guangzhou 510000, China5Guangdong Province Communications Planning & Design Institute Co., Ltd., Xinghua Road, Tianhe District, Guangzhou 510000, China6Department of Civil Engineering and Environment, University of South Carolina, Columbia, SC 29208, USA*Authors to whom correspondence should be addressed. Nanomaterials 2020, 10(4), 641; https://doi.org/10.3390/nano10040641Submission received: 6 March 2020/Revised: 17 March 2020/Accepted: 21 March 2020/Published: 30 March 2020(This article belongs to the Special Issue Preparation and Application of Polymer Nanocomposites)Download keyboard_arrow_downDownload PDFDownload PDF with CoverDownload XMLDownload EpubBrowse Figures Versions Notes Abstract: The storage stability concern, caused by phase separation for the density difference between polymers and asphalt fractions, has limited the widespread application of polymer modified asphalt (PMA). Therefore, this study aims to improve the storage concern of PMA by incorporating nano-montmorillonite. To this end, different nano-montmorillonites were incorporated to three PMAs modified with three typical asphalt modifiers, i.e., crumb rubber (CRM), styrene–butadiene-rubber (SBR) and styrene–butadiene-styrene (SBS). A series of laboratory tests were performed to evaluate the storage stability and rheological properties of PMA binders with nano-montmorillonite. As a consequence, the incorporation of nano-montmorillonite exhibited a remarkable effect on enhancing the storage stability of the CRM modified binder, but limited positive effects for the SBR and SBS modified binders. The layered nano-montmorillonite transformed to intercalated or exfoliated structures after interaction with asphalt fractions, providing superior storage stability. Among selected nano-montmorillonites, the pure montmorillonite with Hydroxyl organic ammonium performed the best on enhancing storage stability of PMA. This paper suggests that nano-montmorillonite is a promising modifier to alleviate the storage stability concern for asphalt with polymer modifiers.Keywords: storage stability; rheological properties; polymer-modified asphalt; nano-montmorillonite

Jiangmiao YuSciProfilesScilitPreprints.orgGoogle Scholar 2,*1Research and Development Centre of Transport Industry of Technologies, Materials and Equipment of Highway Construction and Maintenance, Gansu Road and Bridge Group Co. Ltd., Lanzhou 730050, China2School of Civil Engineering and Transportation, South China University of Technology, Wushan Road, Tianhe District, Guangzhou 510000, China3Key Laboratory for Special Area Highway Engineering, Chang’an University, Xi’an 710064, China4Guangdong Guanyue Highway & Bridge Co., Ltd., Guangzhou 510000, China5Guangdong Province Communications Planning & Design Institute Co., Ltd., Xinghua Road, Tianhe District, Guangzhou 510000, China6Department of Civil Engineering and Environment, University of South Carolina, Columbia, SC 29208, USA*Authors to whom correspondence should be addressed. Nanomaterials 2020, 10(4), 641; https://doi.org/10.3390/nano10040641Submission received: 6 March 2020/Revised: 17 March 2020/Accepted: 21 March 2020/Published: 30 March 2020(This article belongs to the Special Issue Preparation and Application of Polymer Nanocomposites)Download keyboard_arrow_downDownload PDFDownload PDF with CoverDownload XMLDownload EpubBrowse Figures Versions Notes Abstract: The storage stability concern, caused by phase separation for the density difference between polymers and asphalt fractions, has limited the widespread application of polymer modified asphalt (PMA). Therefore, this study aims to improve the storage concern of PMA by incorporating nano-montmorillonite. To this end, different nano-montmorillonites were incorporated to three PMAs modified with three typical asphalt modifiers, i.e., crumb rubber (CRM), styrene–butadiene-rubber (SBR) and styrene–butadiene-styrene (SBS). A series of laboratory tests were performed to evaluate the storage stability and rheological properties of PMA binders with nano-montmorillonite. As a consequence, the incorporation of nano-montmorillonite exhibited a remarkable effect on enhancing the storage stability of the CRM modified binder, but limited positive effects for the SBR and SBS modified binders. The layered nano-montmorillonite transformed to intercalated or exfoliated structures after interaction with asphalt fractions, providing superior storage stability. Among selected nano-montmorillonites, the pure montmorillonite with Hydroxyl organic ammonium performed the best on enhancing storage stability of PMA. This paper suggests that nano-montmorillonite is a promising modifier to alleviate the storage stability concern for asphalt with polymer modifiers.Keywords: storage stability; rheological properties; polymer-modified asphalt; nano-montmorillonite

Graphical Abstract

1. IntroductionWith the extremely increasing loading and aggravation of axis load in the pavement industry, damages such as rutting, cracking etc., are happening more frequently on highways and urban roads [1,2,3,4]. Asphalt modification technology has been considered a practical approach to resolve these concerns by enhancing the durability of asphalt pavements. Crumb rubber (CRM), styrene-butadiene-rubber (SBR) and styrene-butadiene-styrene (SBS) are the three most widely applied modifiers, which are regarded as effective adhesive and cohesive performance enhancers of asphalt [5,6,7,8,9]. However, the storage stability concern of modified asphalt has limited its widespread application. Engineers from asphalt plants have always worried about the separation of the modifier and asphalt during the storage and transportation process in elevated temperatures. According to Stoke’s law, the phase separation phenomenon can be governed by the following equation [10,11,12]: v t= 2 a 2Δρg9η where vt is the settling velocity of dispersed particles, α is the radius of dispersed particles, Δρ is the density difference between two different phases, g is gravitational acceleration, and η is the dynamic viscosity of liquid medium.Among different asphalt modifiers, CRM tends to sink in the liquid phase of modified asphalt during the storage process due to higher density compared to virgin asphalt, while SBR and SBS additives with lower density values tend to float in the upper part of liquid phase. The separation of modifier and raw asphalt results in a huge difference in composition and rheological properties between top and bottom portions of the polymer modified asphalt after storage. Previous studies indicate that this concern can be alleviated by adjusting the liquid asphalt density using bio-modification [13,14] or activating the crumb rubber [15]. However, the improvement effect is not very satisfactory. Therefore, one potential method is addressed in this study by incorporating nanoclay into the polymer-modified asphalt, which can reduce the phase separation phenomenon by decreasing the migration velocity of insoluble additive of polymers in the liquid phase [16,17].Nanoclay is a type of natural mineral mainly including kaolinite clay (KC), vermiculite (VMT) and montmorillonite (MMT), which has a 2:1 layered structure with two silica tetrahedral sheets sandwiching an alumina octahedral sheet. Nowadays, nanomaterials have been popularly applied as modifiers for construction materials [12,18,19,20]. Especially, the importance of layered clay minerals, also known as nanoclays, in terms of asphalt modification is gradually increasing. Nanoclays’ remarkable improvement on the rheological properties of asphalt has been widely reported by previous studies. Vargas et al., [18] discovered that Organo-nanocomposite modified-asphalt can generate an intercalated structure using X-ray diffraction (XRD) and transmission electron microscopy (TEM). This indicates that the enhanced rheological properties may ascribe to the interaction behavior of the polymer chains in asphalt binder into the interlayer of clay. Yu et al., [21] enhanced the storage stability of asphalt rubber by incorporating three types of nanoclays and improved the rheological properties through modification. Leng et al., [22] found that clay/SBS modified bitumen composites have acceptable storage performance. The composites also showed better resistance to aging by reducing the oxidation of bitumen and the degradation of SBS. Galooyak et al., [23] proved the improvement of nanoclays on the storage stability of SBS modified asphalt and confirmed the conclusion through morphological analysis. Thus, nanoclay was expected by the asphalt industry to serve as the storage stability improver of PMAs. The objective of this study was to evaluate the feasibility of alleviating the storage stability concern of polymer-modified asphalt by incorporating nano-montmorillonite. To this end, three different types of nano-montmorillonites and three types of modifiers, i.e., CRM, SBR and SBS, were selected to prepare NPMAs. The rheological tests were performed to evaluate mechanical properties of NPMA binders when applied to pavement industry, among which the Superpave rutting factor test was chosen to control the content of these three modifiers. With the same PG82 grade, the content of modifier applied in each PMA binder was high enough to simulate the most unfavorable situation after storing in high temperature. In addition, the storage stability of modified binders was quantitatively analyzed through characterizing the differences in softening point, complex moduli and absorbance ratio of CRM/SBR/SBS in the infrared spectrum between the top and bottom portions of the sample after a lab-simulated storage process. Finally, an X-ray diffraction (XRD) test was conducted to investigate the layer gap distance variation of nano-montmorillonite to reveal the modification mechanism. 2. Materials and Methods 2.1. Materials and Sample PreparationA Pen 60/70 virgin asphalt, with a penetration grade of 60/70, was used to prepare NPMA binders. In this study, all modified binders including polymer-modified asphalts, nano-montmorillonite-modified asphalts (NMA) and nano-montmorillonite-polymer modified asphalts were prepared by 10,000 rpm high shear incorporating modifiers with a certain dosage into virgin asphalt at 180 °C for 1 h. The selected dosages were 20 wt %, 7 wt % and 6 wt % by virgin asphalt for CRM (40-mesh), SBR and SBS, respectively, then a certain dosage of nano-montmorillonite (3 wt % by virgin asphalt) was adopted to prepare NPMA binders.Three different types of nano-montmorillonites, labelled as A, B and C, were applied for asphalt modification. The nano-montmorillonite samples used in this study are organomodified nanoclay particles (provided by the Zhejiang Fenghong Clay Chemical Co., Ltd., Huzhou, China). The nanoclay samples are high-quality montmorillonite with high purity (at least 95% montmorillonite content). Besides, the nano-montmorillonite layer was forgeable due to the large specific surface area (750 m2/g) and the unique layered one-dimensional nanostructure and morphology. Among the three nanoclays, A is pure montmorillonite with Na+ inorganic group, while B and C are montmorillonites having inorganic groups exchanged with different alkyl ammonium ions. The ranking of their surface hydrophilic properties from high to low is A, B and C. Different from other two-dimensional and three-dimensional inorganic nanoparticles, the specific structure and morphology might lead to excellent mechanical properties, thermal properties, functional properties and physical properties of nano-montmorillonite-polymer modified asphalts. The morphologies of nano-montmorillonites were presented in Figure 1, and the physical properties of different nano-montmorillonites were shown in Table 1. Table 2 detailed the information of each test sample. 2.2. Testing ProgramThe conventional physical properties, including penetration and softening point, were selected as the indicators for the general properties of test binders. The workability was evaluated using a Brookfield viscometer (RVD VII+) through measuring rotational viscosities of asphalt specimen at three different temperatures. The rheological properties of modified binders were characterized using a dynamic shear rheometer (DSR, Malvern Kinexus Lab+, Malvern analytical Company, UK). The Superpave rutting factor (G*/sin δ) test and multiple stress creep recovery (MSCR) tests were conducted to evaluate the high temperature rutting resistance of asphalt samples, while the intermediate temperature fatigue resistance was analyzed through the Superpave fatigue factor (G*sin δ) test and linear amplitude sweep (LAS) test. The test binders for the MSCR test were aged by the standard rolling thin film oven (RTFO) process, while those for the fatigue test were aged by both RTFO and pressure aging vessel (PAV) processes. The bending beam rheometer (BBR) test was also performed to evaluate the low temperature cracking resistance performance of the RTFO + PAV aged samples. The storage stability of modified binders was quantitatively analyzed through characterizing the differences in softening point [16,17], complex moduli [24,25,26] and absorbance ratio of CRM/SBR/SBS in the infrared spectrum between the top and bottom portions of the sample after storing. For FTIR tests, the test binder with a thickness of approximately 1 mm was placed in a transmission holder and scanned in order to obtain infrared spectroscopy ranging from 4,000 to 400 cm−1. According to ASTM 7173 [27], to simulate the high temperature storing process in the laboratory, about 70 g of hot asphalt was poured into an aluminum tube with a diameter of 25 mm. Before cutting the tube into three equal parts horizontally, it was being stored at 163 °C for 48 h followed by cooling down at −5 °C.To investigate the modification mechanism of nano-montmorillonite on storage stability, X-ray diffraction (XRD) tests were conducted to investigate the layer gap distance variation. Table 3 shows the detailed information of conducted tests in this study. 3. Results and Discussion 3.1. Physical PropertiesFigure 2 presents the penetration and softening point results of test binders. It is noted that the polymer-modified asphalts had a higher softening point and a lower penetration, which indicates that the incorporation of CRM/SBR/SBS led to superior performance at high temperature and higher stiffness respectively. It is also observed that the incorporation of nano-montmorillonite further decreased the penetration of SBS-0, while had insignificant effect on CRM-0 and SBR-0. It indicates that the stiffness of SBS modified asphalt binder is more sensitive to nano-montmorillonite compared to the other polymer modified asphalt binders. Different from the penetration results, adding nano-montmorillonite increased the softening points of all modified asphalts. 3.2. WorkabilityFigure 3 presents the workability results, which were evaluated by the Brookfield rotational viscosity tests. The higher the viscosity value was, the worse workability the test binder had. According to previous studies [28,29,30], poor workability is one of the most critical concerns limiting the spread of asphalt rubber. As expected, CRM modified asphalt binders had extremely higher viscosities than other test binders at all temperatures. Besides, the viscosities of SBR/SBS modified binders except SBS-C were below 3000 cP at 135 °C, which indicates the mixtures with these binders can be compacted according to the AASHTO (American Association of State Highway and Transportation Officials) specification. 3.3. Rutting PerformanceFigure 4b shows the rutting factor (G*/sin δ) values at different temperatures. The starting temperature was set as 64 °C, then the test temperature was automatically increased by 6 °C until the rutting factor was below 1.0 kPa (the critical value for unaged binders). Figure 4a presents the critical temperature results. The higher the critical temperature was, the superior rutting resistance the test binder had. As expected, all of the three polymer modifiers led to much higher critical temperatures than virgin asphalt. It is noted that adding nano-montmorillonite had insignificant effect on SBR-0 and SBS-0. However, the incorporation of nano-montmorillonite further enhanced the rutting resistance of CRM-0, indicating that nano-montmorillonite worked much better with CRM modified binders than SBR/SBS modified binders in terms of rutting resistance.The MSCR test results were presented in Table 4. Lower Jnr values and higher % Recovery values refers to superior pavement rutting resistance performance. It is noted that SBS modified binders with nano-montmorillonite and all CRM modified binders did not meet the requirement of AASHTO specification, i.e.,